| |

|

|

| |

|

|

| |

Quality System Roadmap

Since its establishment in 1994, the pursuit of Zero Defects has always been a core value and main focus of Emerging Display Technologies Corporation. Mr. Ray Tseng, Chairman and founder of EDT, comes from a quality control background which instilled in him a strong belief and commitment for high performance and superior quality. From day one EDT established a multi-phased, comprehensive Quality System Roadmap that has evolved over time with industry quality standards. |

Phase 1 (1994~2003) - Institutional construction period

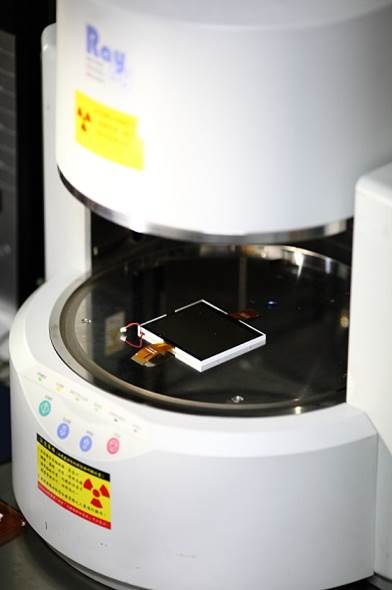

To ensure that our products have high level quality and long term stability, the EDT team worked hard to establish the company’s own reliability laboratory and invested in necessary equipment to ensure quality control for customers and continuously promote quality in-house. During this period, EDT: |

- Obtained ISO9002 certification which assured quality on product assembly, installation and service guarantee

- Was awarded QS9000, and ISO9001:2000 certification for incorporating design and development into regulation, system documentation and continuous improvement on quality management system for customers' satisfaction

- Actively embraced Pb-free products and was proud to be the first Taiwanese display manufacturer to release lead-free products to the market

|

|

Phase 2 (2004~2010) - Scientific validation & Green product period

Within EDT, “Quality” took on a much wider and deeper meaning. It was not restricted to products and process alone but also social responsibility. During the period, EDT: |

|

- Continued active engagement in driving green products, within international requirements to promote RoHS compliant & REACH compatible products

- Was certified ISO 14001 and made efforts to reduce energy loss and environmental pollution

- Has continually driven consistency of quality level by adopting 6-sigma methodology

- Engaged in automotive products and obtained ISO/TS16949 certification

|

Phase 3 (2011~2015) - GP & Manufacturing Optimization Period

EDT recognizes the importance of global environmental conservation and creation of a sustainable society. Additional effort and focus has been made on process waste reduction plans and recycling of packing materials. During this phase, EDT: |

- Committed to development of environmental sustainability, was awarded QC080000 certification and reduced the use of hazardous substances in our manufacturing processes

- Received OHSAS 18001 certification and catered to health and safety of employees

|

|

Phase 4 (2016~) - Lean Manufacturing Period

EDT has embraced a multi-faceted strategy which includes richly cultivating integration of various technologies and adding product solutions for the value market segment. Step by step, EDT is establishing lean production with low volume-high mix capabilities, and maximizing the utilization of resources to make strides in an important core value, "waste elimination". Additionally, EDT is evolving to support the latest quality certifications and to promote contemporary management systems. During this phase, EDT continues to: |

- Establish MES (Manufacturing Execution System) to achieve optimization of manufacturing quality and Pull-APS (Advanced Planning and Scheduling) to promote manufacturing efficiency. Both systems (MES & Pull-APS) complement each other to achieve lean manufacturing objectives while maintaining high quality and advancing efficiency

- Establish QCFA (Quick Change Flexible Assembly line) to achieve "low volume-high mix manufacturing" and "lean and win-win of quality and efficiency"

- Renew ISO-14001:2015 and IATF 16949 certification

- EDT has implemented and is fully certified for ISO13485:2016, the internationally recognized standard for a quality management system specific to the medical devices industry

|

|

Environmental Policy

EDT is fully devoted to conservation of global environment and creation of a sustainable society for future generations. Apart from fully supporting PB-free and RoHS compliance products in 2002 and 2005 respectively, EDT independently started our own GP initiatives in 2007. Since that time our company has made increasing and continuous effort to protect the environment through the following: |

|

- Leading and requesting our entire supply chain base to commit to and comply with our GP requirements.

- Developing green products which are in compliance with international environmental & safety regulations

- Reinforcing energy saving and pollution prevention in every process.

- Organizing internal training and safety awareness program for all employees.

- Implementation of environmental management system to control environmental risks and insistence on continual improvement.

|

Occupational Safety & Health Policy |

|

|

|

EDT has a sound occupational safety and health policy in place to ensure health, hygiene and safety for all employees and is an OHSAS 18001 certified company. A comprehensive occupational safety and health system can prevent employees from occupational accidents and illnesses, and the company from fire or other dangerous events. Each and every employee of EDT believes that effective risk management and practice of safe and clean working environment leads to business continuity and, ultimately, enhancement of productivity and customer satisfaction. |

|

|

|

|

| |

|

|

|

|

![]() |